Wholesale or OEM Helical Screw Compressor

Combining scientific design and excellent manufacturing technology, the atmospheric screw air compressor is equipped with an advanced screw airend module, a stable and reliable drive motor, an intelligent and efficient cooling system, and a control module to provide strong and stable air power for your end use. Based on the concept of energy saving, consumption reduction, stability and durability, AULISS atmospheric screw air compressor such as oil injected permanent magnet screw air compressor adopts advanced German airend and production technology to ensure reliable, stable and continuous operation and running of the compressors under various working conditions.

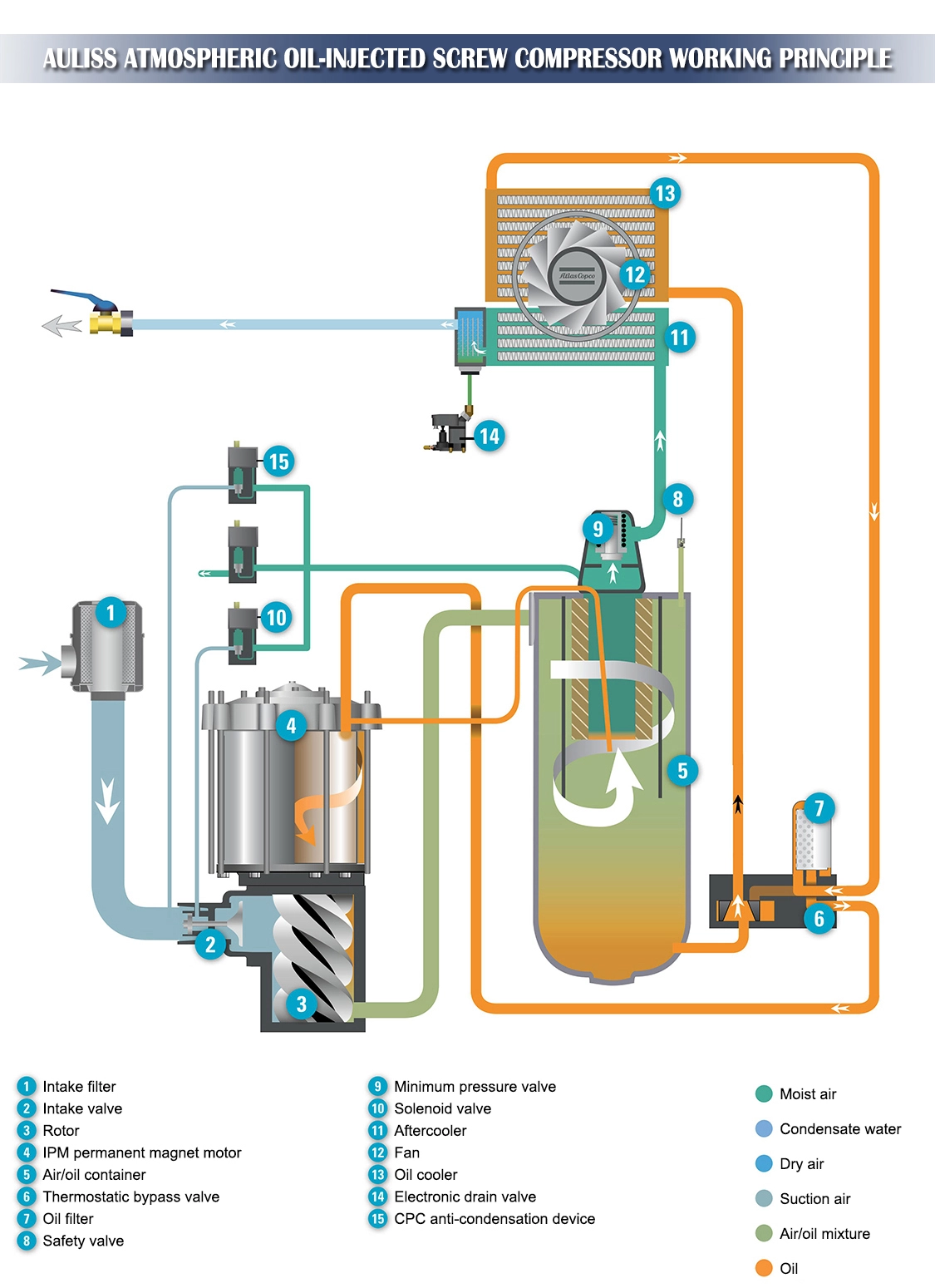

The working principle of an atmospheric pressure oil-injected screw compressor involves several key steps. Initially, atmospheric air enters the compressor through an intake filter. Inside the oil injected screw air compressor, a pair of interlocking rotors with helical screw profiles draw in the air and compress it as they rotate. During compression, injected oil serves multiple purposes: sealing the gaps between rotors to prevent air leakage, cooling the compressed air, and lubricating moving parts for smooth operation. The compressed air-oil mixture then moves to a separator where oil is removed, ensuring clean compressed air output. Finally, the air is stored in a receiver tank for distribution to various applications. This process enables efficient compression and delivery of compressed air for industrial and commercial use.

▶ Premium-Grade Metals: AULISS utilizes top-tier metals in the construction of our helical rotary screw compressors. These high-quality materials provide exceptional strength and resistance to wear, ensuring a longer operational lifespan.

▶ Corrosion-Resistant Coatings: Our compressors are treated with advanced corrosion-resistant coatings. This protective layer shields the internal and external components from environmental factors, enhancing durability and reducing maintenance needs.

▶ High-Performance Alloys: The use of high-performance alloys in critical components of our helical rotary compressors ensures superior thermal stability and mechanical strength. This results in reliable performance even under extreme conditions.

▶ Precision Machining: AULISS employs precision machining techniques to fabricate each part of our compressors. This meticulous attention to detail ensures perfect fitting and alignment, reducing stress on materials and extending the life of both helical rotary and micro screw compressor.

Before maintenance, the unit should be stopped, the exhaust valve closed, disconnect the unit power supply and hang a warning sign, and the pressure in the unit should be emptied (each pressure gauge shows "0") before starting the oil injected rotary screw compressor maintenance work. When disassembling the high-temperature components, the temperature must be cooled down to the ambient temperature before proceeding.

Use the correct tools to repair the oil injected screw air compressor.

Recommend the use of special oil for industrial screw type air compressor, and do not allow mixing of different grades of lubricating oil after maintenance.

The original air compressor spare parts are specially designed and manufactured, and it is recommended to use genuine spare parts to ensure the reliability and safety of the air compressor.

Without the permission of the rotary air compressor manufacturers, do not make any changes to the oil injected screw air compressor that will affect the safety and reliability or add any devices.

An oil injected screw air compressor is a common power equipment, a device that converts mechanical energy into gas pressure energy. In simple terms, it is a gas pressure generating device for compressed air. The role of the oil injected screw compressor is mainly for gas supply, to provide the gas needed for production. The use of this micro screw compressor is relatively wide common:

The traditional air power: wind-powered tools, rock drills, pickaxes, pneumatic wrenches, pneumatic sandblasting.

Instrumentation control and automation devices, such as machining centers for tool replacement.

Food, pharmaceutical industry, the use of compressed air to mix the slurry.

Large marine diesel engine starting.

The role and use of oil injected rotary screw compressor wind tunnel experiments, underground passageway air exchange, metal smelting.

AULISS, a professional screw type air compressor supplier, manufactures the atmospheric oil injected screw air compressor that adopts advanced air end and production technology to ensure reliable, stable and continuous operation and running of the oil injected permanent magnet screw compressor under various working conditions.