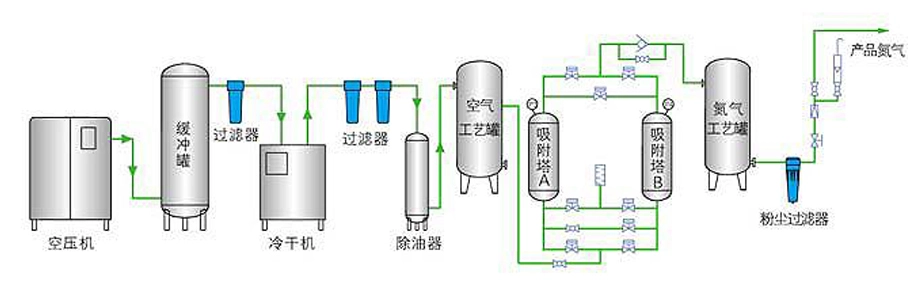

In compressed air systems, in addition to air compressors to produce compressed air, post-treatment equipment is needed to cool, dry and purify the air. In general, the air compressor post-processing equipment commonly used are air storage tanks, filters and dryers.

According to the principle of refrigeration dehumidification, the saturated compressed air from the upstream is cooled to a certain dew point temperature through the heat exchange with the refrigerant, and a large amount of liquid water is condensed out of the machine after the separation of the gas-liquid separator, so as to achieve the purpose of water drying. The drying machine is based on the principle of pressure swing adsorption, the saturated compressed air from the upstream is in contact with the desiccant under a certain pressure, the vast majority of the water is adsorbed in the desiccant, and the dry air enters the downstream to work, so as to achieve the purpose of deep drying.

The filter element is composed of fiber medium, filter screen, sponge and other materials. Solid and liquid particles (drops) in the compressed air are intercepted by the filter material and condensed on the surface of the filter element (inside and outside). The droplets and impurities accumulated on the surface of the filter element are precipitated to the bottom of the filter by the action of gravity and then discharged by the automatic drainer or artificial.

When the air passes through the gas tank, the high-speed air flow hits the wall of the gas tank to produce a confluent flow, and the temperature in the gas tank drops rapidly, so that a large amount of water vapor is liquefied, thereby removing a large amount of water and oil.

Compressed air treatment equipment including China compressed air filter contributes to energy savings by efficiently removing moisture, contaminants, and particulates from compressed air systems. This type of wholesale screw air compressor ensures optimal air quality, preventing equipment inefficiencies, corrosion, and pressure drops. By maintaining clean and dry air, these treatments reduce the workload on compressors, leading to lower energy consumption and prolonged equipment lifespan.

Ensure that the automatic drainer drains normally, and clean up if it cannot drain.

Clean the air filter of the host once a week.

Observe the operation to see whether the pressure at the high and low pressure end of the refrigerant and the pressure of each instrument and pipeline are indicated in the normal operating position.